Instantaneous inspection machine

HN-100 Pro & HN-1030 Pro Series | HN-100WS Horizontal One-Touch Instantaneous Inspection Machine | HN-190Pro Series | HN-3020Plus Series

Instantaneous inspection machine

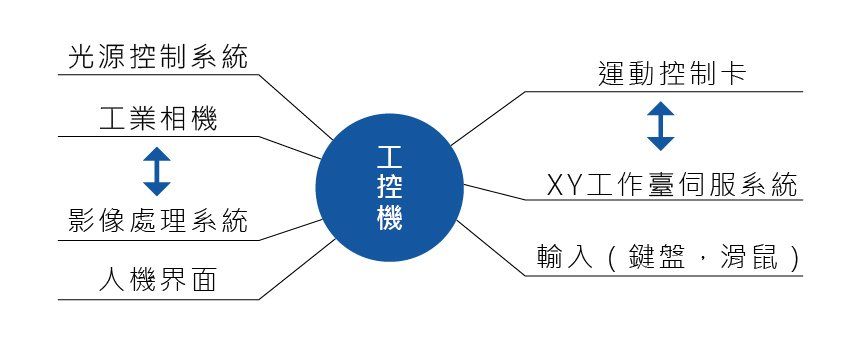

Vision System

Software system

AOI automatic inspection software can be flexibly combined with machine vision systems. It is a component of automatic optical inspection systems or equipment. It is mainly used in factory automation inspection. It can control product quality during the production process, collect product information, etc. Product classification can also be integrated into the inspection function.

HN-100 Pro&HN-1030 Pro Series

| Device parameters | HN-100 Pro & HN-1030 Pro |

|---|---|

| Image sensor | 20-megapixel CMOS |

| monitor | 21-inch LCD display |

| lens | Bilateral telecentric lens |

| Lighting system-transmission system | Telecentric transmission illumination (color: green) |

| Lighting system-Episcopic system | Programmable LED (color: white) |

| Lighting system-coaxial light source | Coaxial epi-light source (optional) |

| Measuring field of view | Wide field of view (100x80mm) |

| Image measurement repeatability | Wide field of view (±1.5μm) |

| Image measurement accuracy | Wide field of view (±3μm) |

| Measurement software | CX-Vision V1.0 |

| Display resolution | 0.1μm |

| Z-axis electric coordinate stage | Moving range 40mm |

| Dimensions (L×W×H) | 380×220×728(mm) |

| load-bearing | 3KG |

| weight | 18KG |

| Working power supply | AC220V/50Hz |

| Work Environment | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz |

HN-100WS Horizontal One-button Instantaneous Inspection Machine

| Device parameters | HN-100WS |

|---|---|

| Image sensor | 20-megapixel CMOS |

| monitor | 21-inch LCD display |

| lens | Bilateral telecentric lens |

| Lighting system-transmission system | Telecentric transmission illumination (color: green) |

| Lighting system-Episcopic system | LED lighting (color: white) |

| Measuring field of view | Wide field of view (100x80mm) |

| Image measurement repeatability | Wide field of view (±1.5μm) |

| Image measurement accuracy | Wide field of view (±3μm) |

| Measurement software | CX-Vision V1.0 |

| Display resolution | 0.1μm |

| X-axis automatic lens focus | Movement range 40 |

| Electric rotating coordinate table | 360-degree rotation |

| Dimensions (L×W×H) | 715×255×366(mm) |

| load-bearing | 3KG |

| weight | 21KG |

| Working power supply | AC220V/50Hz |

| Work Environment | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz |

HN-190Pro Series

| Device parameters | HN-190Pro |

|---|---|

| Image sensor | 25-megapixel CMOS |

| monitor | 21-inch LCD display |

| lens | Bilateral telecentric lens |

| Lighting system-transmission system | Telecentric transmission illumination (color: green) |

| Lighting system-Episcopic system | LED lighting (color: white) |

| Lighting system-coaxial light source | Coaxial epi-light source (optional) |

| Measuring field of view | Wide field of view (190x120mm) |

| Image measurement repeatability | Wide field of view (±1.5μm) |

| Image measurement accuracy | Wide field of view (±3μm) |

| Measurement software | CX-Vision V1.0 |

| Display resolution | 0.1μm |

| Z-axis electric coordinate stage | Movement range: 135 |

| Dimensions (L×W×H) | 800×910×1850(mm) |

| load-bearing | 10KG |

| weight | 105KG |

| Working power supply | AC220V/50Hz |

| Work Environment | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz |

HN-3020Plus Series

| Device parameters | HN-1220 | HN-1220P |

|---|---|---|

| Image sensor | 20-megapixel CMOS | 20-megapixel CMOS |

| monitor | 14-inch LCD display (XGA: 1024×768) | 14-inch LCD display (XGA: 1024×768) |

| lens | Bilateral telecentric lens | Bilateral telecentric lens |

| Lighting system-transmission system | Telecentric transmission illumination (color: green) | Telecentric transmission illumination (color: green) |

| Lighting system-Episcopic system | LED lighting (color: white) | LED lighting (color: white) |

| Measurement field of view - wide field of view | 20xL120 mm | 20xL120 mm |

| Measuring field of view - high precision | / | 6xL120 mm |

| Image measurement repeatability - wide field of view | The coordinate stage does not move (±0.5μm) | The coordinate stage does not move (±0.5μm) |

| Image measurement repeatability - wide field of view | Coordinate table movement (±1μm) | Coordinate table movement (±1μm) |

| Image measurement repeatability-high precision | / | The coordinate stage does not move (±0.1μm) |

| Image measurement repeatability-high precision | / | Coordinate table movement (±0.5μm) |

| Image measurement accuracy - no stitching | Wide field of view (±2μm) | Wide field of view (±2μm) |

| Image measurement accuracy - no stitching | / | High precision (±0.7μm) |

| Image measurement accuracy - with stitching | Wide field of view ±(4 0.02L)μm | Wide field of view ±(4 0.02L)μm |

| Image measurement accuracy - with stitching | / | High precision ±(2 0.02L)μm |

| Measurement software | CX-Vision V1.0 | CX-Vision V1.0 |

| Display resolution | 0.1μm | 0.1μm |

| XY electric worktable | X moving range 100mm | X moving range 100mm |

| Z-axis electric coordinate stage | Moving range 35mm | Moving range 35mm |

| Dimensions (L×W×H) | 623×473×750(mm) | 623×473×750(mm) |

| load-bearing | 3KG | 3KG |

| weight | 30KG | 30KG |

| Working power supply | AC220V/50Hz | AC220V/50Hz |

| Work Environment | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz |

| Device parameters | HN-2010 | HN-2010P |

|---|---|---|

| Image sensor | 20-megapixel CMOS | 20-megapixel CMOS |

| monitor | 10.4-inch LCD display (XGA: 1024×768) | 10.4-inch LCD display (XGA: 1024×768) |

| lens | Bilateral telecentric lens | Bilateral telecentric lens |

| Lighting system-transmission system | Telecentric transmission illumination (color: green) | Telecentric transmission illumination (color: green) |

| Lighting system-Episcopic system | LED lighting (color: white) | LED lighting (color: white) |

| Measurement field of view - wide field of view | Φ100×L200 | Φ100×L200 |

| Measuring field of view - high precision | / | 20xL120 mm |

| Image measurement repeatability - wide field of view | Coordinate table not moving (±1μm) | Coordinate table not moving (±1μm) |

| Image measurement repeatability - wide field of view | Coordinate table movement (±2μm) | Coordinate table movement (±2μm) |

| Image measurement repeatability-high precision | / | The coordinate stage does not move (±0.5μm) |

| Image measurement repeatability-high precision | / | Coordinate table movement (±1.5μm) |

| Image measurement accuracy - no stitching | Wide field of view (±5μm) | Wide field of view (±5μm) |

| Image measurement accuracy - no stitching | / | High accuracy (±2μm) |

| Image measurement accuracy - with stitching | Wide field of view ±(7 0.02L)μm | Wide field of view ±(7 0.02L)μm |

| Image measurement accuracy - with stitching | / | High precision ±(4 0.02L)μm |

| Measurement software | CX-Vision V1.0 | CX-Vision V1.0 |

| Display resolution | 0.1μm | 0.1μm |

| XY electric worktable | X moving range 100mm | X moving range 100mm |

| Z-axis electric coordinate stage | Moving range 35mm | Moving range 35mm |

| Dimensions (L×W×H) | 623×473×750(mm) | 623×473×750(mm) |

| load-bearing | 5KG | 5KG |

| weight | 38KG | 38KG |

| Working power supply | AC220V/50Hz | AC220V/50Hz |

| Work Environment | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz |

| Device parameters | HN-2020 | HN-2020P |

|---|---|---|

| Image sensor | 20-megapixel CMOS | 20-megapixel CMOS |

| monitor | 14-inch LCD display (XGA: 1024×768) | 14-inch LCD display (XGA: 1024×768) |

| lens | Bilateral telecentric lens | Bilateral telecentric lens |

| Lighting system-transmission system | Telecentric transmission illumination (color: green) | Telecentric transmission illumination (color: green) |

| Lighting system-Episcopic system | LED lighting (color: white) | LED lighting (color: white) |

| Measurement field of view - wide field of view | 200×200 (4 corners R50) | 200×200 (4 corners R50) |

| Measuring field of view - high precision | / | 120x120 mm |

| Image measurement repeatability - wide field of view | Coordinate table not moving (±1μm) | Coordinate table not moving (±1μm) |

| Image measurement repeatability - wide field of view | Coordinate table movement (±2μm) | Coordinate table movement (±2μm) |

| Image measurement repeatability-high precision | / | The coordinate stage does not move (±0.5μm) |

| Image measurement repeatability-high precision | / | Coordinate table movement (±1.5μm) |

| Image measurement accuracy - no stitching | Wide field of view (±5μm) | Wide field of view (±5μm) |

| Image measurement accuracy - no stitching | / | High accuracy (±2μm) |

| Image measurement accuracy - with stitching | Wide field of view ±(7 0.02L)μm | Wide field of view ±(7 0.02L)μm |

| Image measurement accuracy - with stitching | / | High precision ±(4 0.02L)μm |

| Measurement software | CX-Vision V1.0 | CX-Vision V1.0 |

| Display resolution | 0.1μm | 0.1μm |

| XY electric worktable | X moving range 100mm | X moving range 100mm |

| XY electric worktable | Y moving range 100mm | Y moving range 100mm |

| Z-axis electric coordinate stage | Moving range 75mm | Moving range 75mm |

| Dimensions (L×W×H) | 60x105(mm) | 60x105(mm) |

| Maximum measuring depth | 75mm | 75mm |

| Probe diameter | Φ1mm | Φ1mm |

| Measuring force | 0.13N | 0.13N |

| Dimensions (L×W×H) | 623×473×750mm | 623×473×750mm |

| load-bearing | 5KG | 5KG |

| weight | 45KG | 45KG |

| Working power supply | AC220V/50Hz | AC220V/50Hz |

| Work Environment | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz |

| Device parameters | HN-3020 | HN-3020P |

|---|---|---|

| Image sensor | 20-megapixel CMOS | 20-megapixel CMOS |

| monitor | 14-inch LCD display (XGA: 1024×768) | 14-inch LCD display (XGA: 1024×768) |

| lens | Bilateral telecentric lens | Bilateral telecentric lens |

| Lighting system-transmission system | Telecentric transmission illumination (color: green) | Telecentric transmission illumination (color: green) |

| Lighting system-Episcopic system | LED lighting (color: white) | LED lighting (color: white) |

| Measurement field of view - wide field of view | 300×200 (4 corners R50) | 300×200 (4 corners R50) |

| Measuring field of view - high precision | / | 230x130 mm |

| Image measurement repeatability - wide field of view | Coordinate table not moving (±1μm) | Coordinate table not moving (±1μm) |

| Image measurement repeatability - wide field of view | Coordinate table movement (±2μm) | Coordinate table movement (±2μm) |

| Image measurement repeatability-high precision | / | The coordinate stage does not move (±0.5μm) |

| Image measurement repeatability-high precision | / | Coordinate table movement (±1.5μm) |

| Image measurement accuracy - no stitching | Wide field of view (±5μm) | Wide field of view (±5μm) |

| Image measurement accuracy - no stitching | / | High accuracy (±2μm) |

| Image measurement accuracy - with stitching | Wide field of view ±(7 0.02L)μm | Wide field of view ±(7 0.02L)μm |

| Image measurement accuracy - with stitching | / | High precision ±(4 0.02L)μm |

| Measurement software | CX-Vision V1.0 | CX-Vision V1.0 |

| Display resolution | 0.1μm | 0.1μm |

| XY electric worktable | X moving range 210mm | X moving range 210mm |

| XY electric worktable | Y moving range 110mm | Y moving range 110mm |

| Z-axis electric coordinate stage | Moving range 75mm | Moving range 75mm |

| Dimensions (L×W×H) | 60x110(mm) | 60x110(mm) |

| Maximum measuring depth | 75mm | 75mm |

| Probe diameter | Φ1mm | Φ1mm |

| Measuring force | 0.13N | 0.13N |

| Dimensions (L×W×H) | 623×473×750mm | 623×473×750mm |

| load-bearing | 5KG | 5KG |

| weight | 50KG | 50KG |

| Working power supply | AC220V/50Hz | AC220V/50Hz |

| Work Environment | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz | Temperature 10℃~35℃, humidity 30~80%, vibration <0.002g, less than 15Hz |