Visual software

Intelligent Vision System

- There are many controllers to choose from, including high-speed and normal.

- Supports various output methods such as IO, RS232 and Ethernet.

- Use solid-state hard drives to ensure long-term stable operation.

- Up to 4 cameras can be connected at the same time.

- Supports wireless mouse operation.

- Support external storage.

A comprehensive geometric measurement tool for detecting points, lines, circles, distances, widths, pitches, angles, midpoints, centers of gravity, concave and convex points, perpendicular lines, and center lines, meeting all industry dimensional measurement requirements.

Contour Search

This processing tool strives for high processing power, speed, and precision in harsh inspection environments. It extracts contour information from objects for search. Even if the search object has defects, contrast loss, or size changes, it maintains stable search capabilities. It also provides a position correction source for other tools, demonstrating its superior search capabilities.

- High stability search

- High-speed processing capabilities

- High Precision Standard

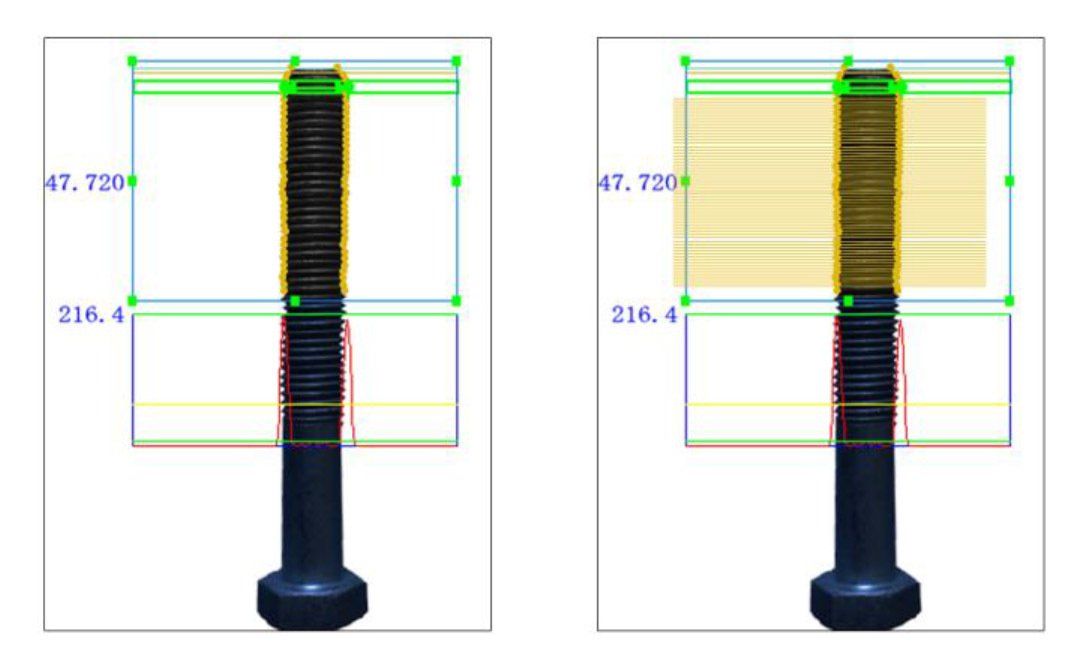

Trend Edge/Position Width

Up to 5,000 points can be detected within a range. This tool detects edges at up to 5,000 points within the detection range and outputs their positions and widths. It can also detect maximum, minimum, and average widths, bottom positions, and peak-to-peak widths without requiring complex calculations. Furthermore, virtual circles and straight lines can be generated by detecting multiple points.

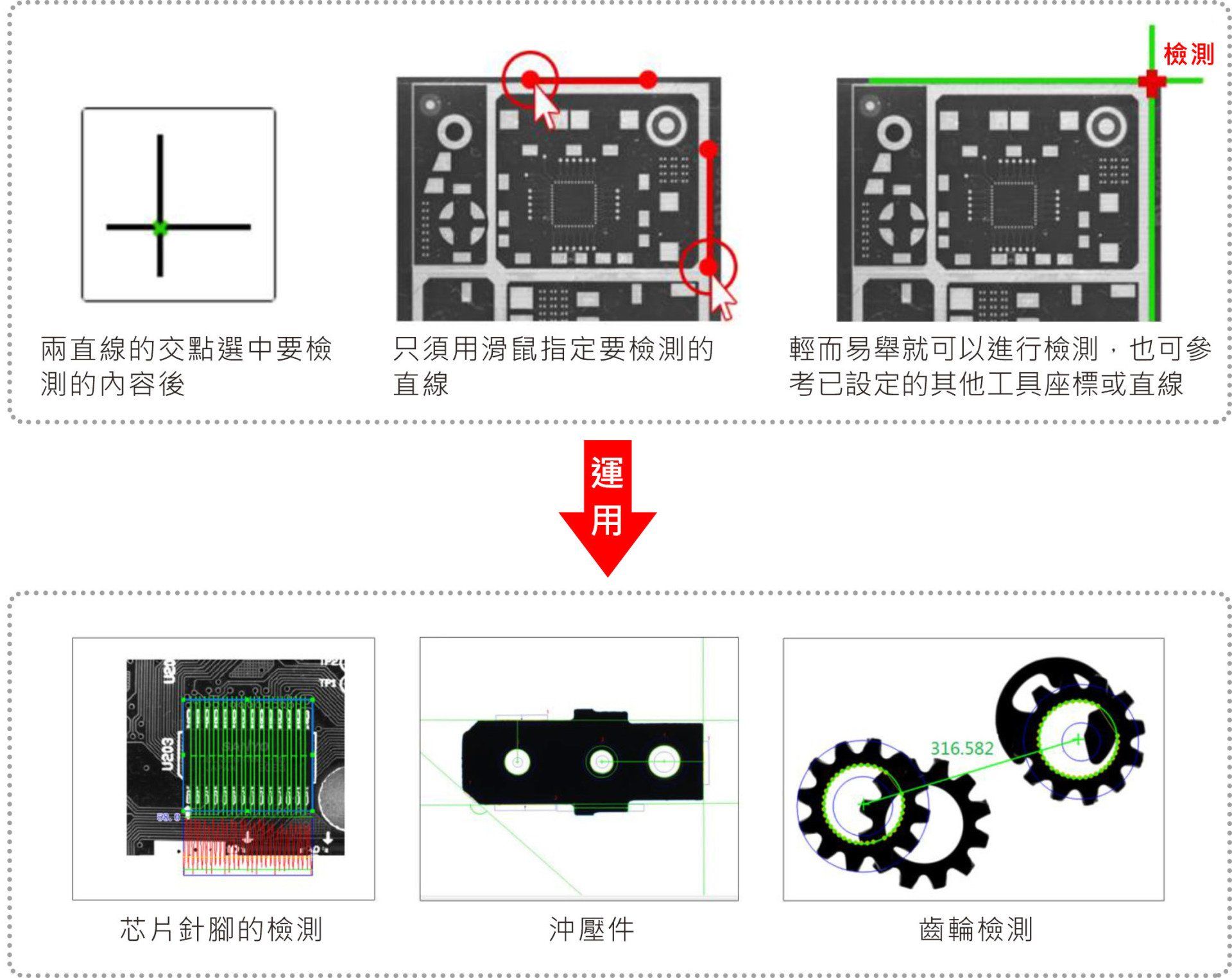

Geometric measurement tools

High-precision dimensional inspection is achieved with simple, intuitive operation. Geometric measurement through graphics processing typically requires multiple inspection tools and complex calculations. The SV Series features geometric measurement tools that handle these complex processes with a single mouse click. They can also reference point or line information from other tools, making it easier to create easy-to-use inspection settings.

- Just click the mouse to complete the setting

- Rich geometry tools are just a matter of selection

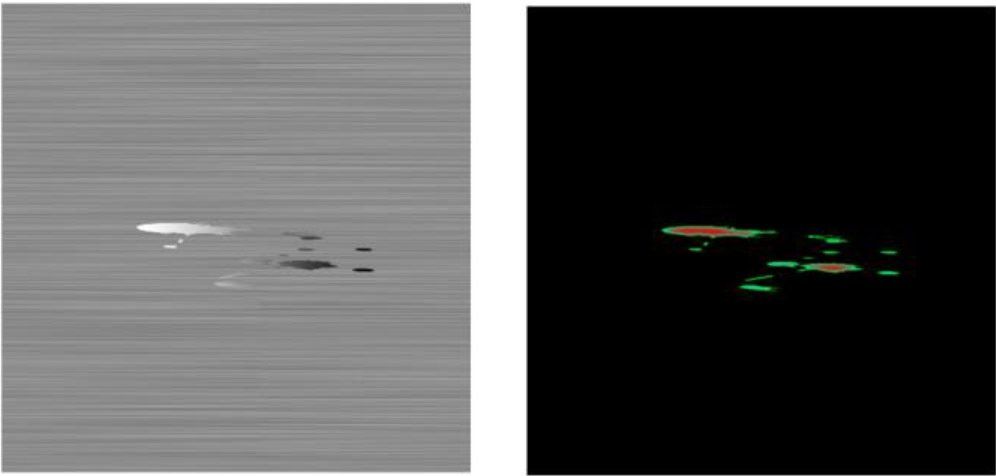

flaw

The tool has stable detection performance and sets the industry standard.

This tool detects flaws and stains while comparing them with the surrounding light and dark areas. It not only has excellent detection performance but can also filter out defects based on size, density, shape, number, etc.

This function can color the defect according to the difference in density between the defect and its surroundings, distinguishing the actual location to be inspected from the background and visually presenting the degree of difference very intuitively. The inspected image can be confirmed not only during setup but also during operation. This allows for more flexible and effective tracking of the causes of erroneous detections. The portion with a density difference will be displayed graphically from green to red. In addition, the background and the defect to be inspected are displayed with high contrast, and the shape, size, and location of the defect are clearly presented.

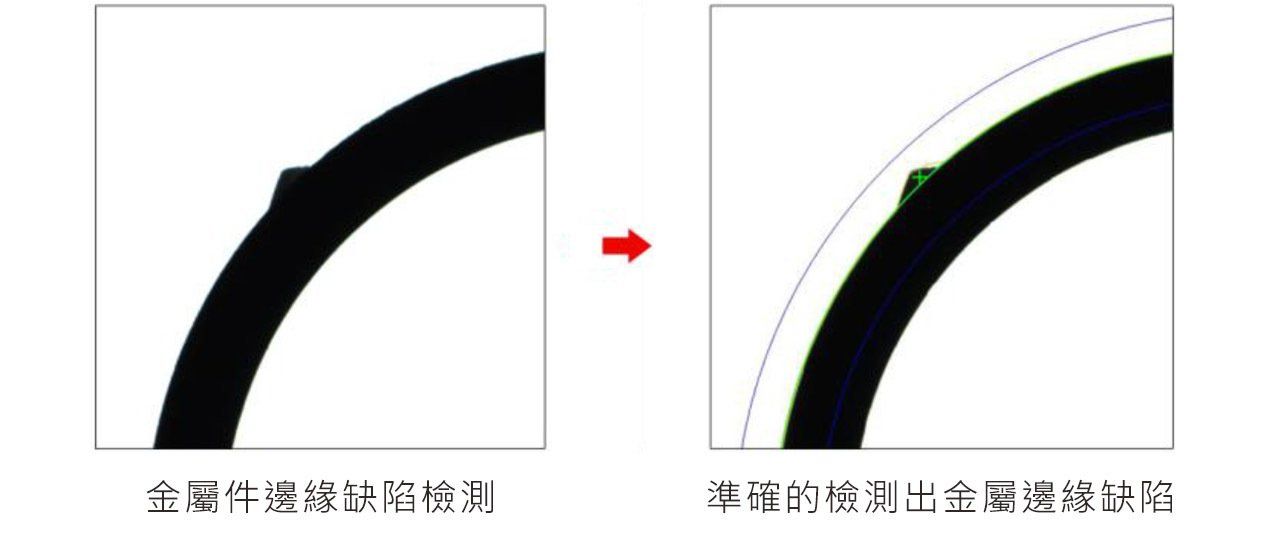

Detection of trend edges

This tool is ideal for detecting burrs, flaws, and contour defects. It extracts a contour from an edge and identifies areas that differ significantly from that contour as burrs/defects. Based on up to 5,000 points of edge information, it supports detection of not only circles and straight lines, but also complex contours such as ellipses and free-form curves.

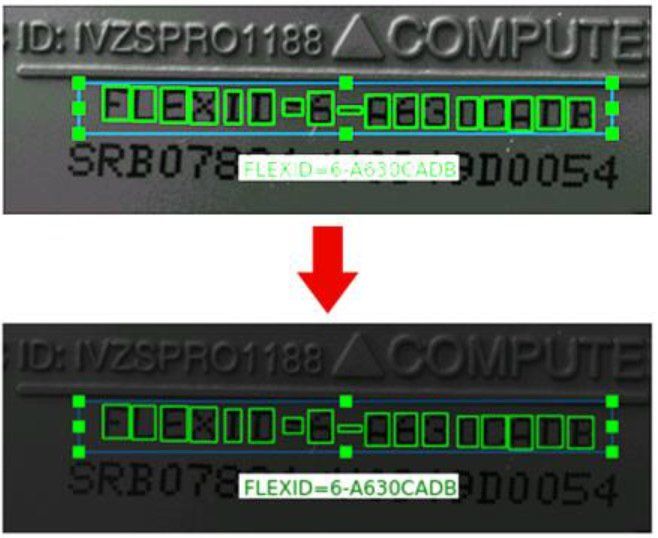

OCR

This accurate and fast character recognition tool visualizes the cutting and inspection process. It can recognize printed and engraved characters on products. To cope with the ever-changing character engraving conditions on the inspection site, the SV series products are dedicated to visualizing the character cutting, inspection process, and character library.

- Strong adaptability to brightness changes

- The accuracy of its detection is presented through numerical values

- Character library with powerful processing capabilities

Barcode/QR code reading

Perform reading and image processing detection at the same time

Reads barcodes/QR codes engraved on target workpieces. Simultaneously reading barcodes and performing image inspection and processing using other tools within the field of view saves space and reduces costs compared to conventional methods of distributing barcode/QR code reading and image processing. A QR code engraving quality verification function has been added, allowing for online verification of any changes in engraving quality while reading the engraving. Supports ISO/IEC 15415, AIM DPM-1-2006, and SAEAS 9132 verification methods.

Barcode and QR code recognition cases